UV curable resins cause curing inhibition by oxygen in the atmosphere. The effect of inhibiting oxygen inhibition in UV irradiation under inert gas without oxygen has been known for a long time.

CSN2-40 has been developed so that it can be offered at a lower price than conventional nitrogen purge UV devices due to its mass production effect.

①Resin can be cured in a nitrogen purge atmosphere or normal atmosphere.

②Experiments can be performed in a low oxygen atmosphere with low nitrogen consumption.

③Experiments can be performed over a wide range of light conditions despite its compact size.

④Since an inverter type power supply is used, experiments under stable light conditions are possible.

⑤Digital display of transport speed, UV output and oxygen concentration.

⑥The device automatically controls the set parameters.

⑦An oxygen sensor for indoor monitoring is provided as standard to prevent oxygen deficiency and can be used safely.

| UV lamp | Mercury lamp or metal halide lamp 4kW(160W/cm) |

| Lamp output | 1kW to 4kW stepless volume adjustment |

| UV irradiation equipment | Cold mirror (condensing type) |

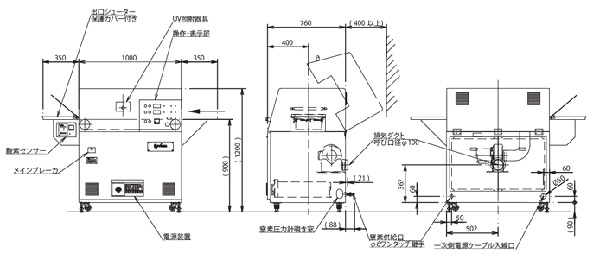

| Irradiated object | W220 × L320 × T2mm (A4 size) Weight 500g or less |

| Irradiation distance | Fixed 80mm from the bottom of the UV irradiation device to the conveyor surface |

| Transport system | Transfer speed: 5 to 90m / min Opening height: 5mm fixed Aperture width: 240mm (effective irradiation range 200mm) |

| In-furnace oxygen sensor | 0.1 to 25% measurement (overall accuracy ± 1% FS) |

| Oxygen sensor | 1 location included |

| Device exterior color | Japan Paint Industry Association A22-90B semi-gloss (cream) |

| Estimated quality | 250kg |

| usage environment | Temperature: 5-40 ° C Humidity: 85% or less (no condensation) |

| Power supply | 200VAC(190~230VAC) 3-phase 50/60Hz 7.5kVA |

| Nitrogen pressure | 0.5MPa 50L/min(MAX) |

| exhaust | φ100mm 約4m3/min |

※Since some ozone is discharged, please discharge it outdoors.

※The exhaust duct from the equipment exhaust port should be constructed by the customer.